How are textiles classified according to processing materials?

2023-07-27

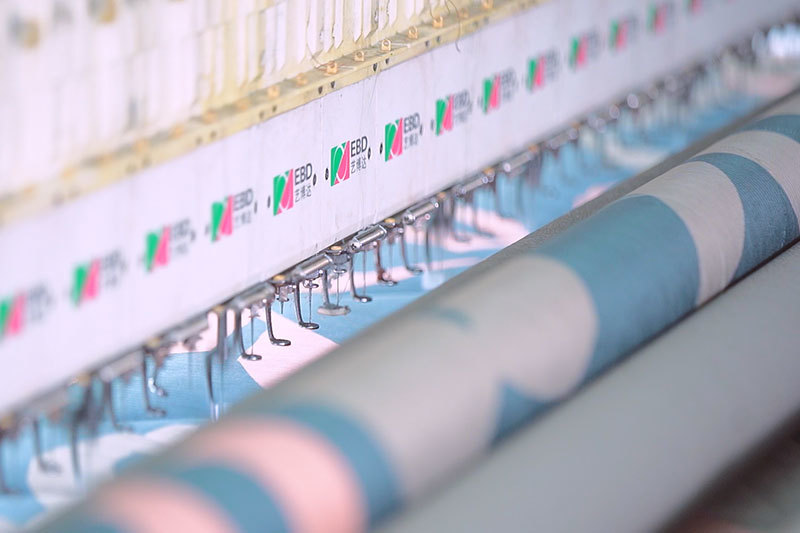

Cotton spinning silk processing linen spinning wool spinning chemical fiber

It can also be divided according to the weaving method:

Knitted woven nonwoven

Chemical processing exists in every process, but the chemical fiber industry and dyeing and finishing industry have the most chemical processing.

Common concepts:

(1) Warp direction, warp yarn, warp density - the length direction of the fabric; the yarns in this direction are called warp yarns; the number of yarns arranged within 1 inch is the warp density (warp density).

(2) Weft direction, weft yarn, and weft yarn density - the width direction of the fabric; the yarns in this direction are called weft yarns, and the number of yarns arranged within 1 inch is the weft density (weft yarn density).

(3) Density - used to indicate the number of yarns per unit length of woven fabrics, generally the number of yarns within 1 inch or 10 centimeters. my country's national standards stipulate that the number of yarns within 10 centimeters is used to indicate density. However, textile companies are still accustomed to using the number of yarns within 1 inch to express density. For example, the commonly seen "45×45/108×58" means that the warp and weft threads are 45 respectively, and the warp and weft densities are 108 and 58.

(4) Width - the width of the fabric, generally expressed in inches or centimeters, the common ones are 36 inches, 44 inches, 56 to 60 inches, etc., which are called narrow width, medium width and wide width respectively, higher than 60 inches The fabric is extra wide, often called wide cloth. The width of extra wide fabric in my country today can reach 360 cm. The width is generally marked after the density. For example, if the fabric mentioned in 3 is added with the width, it will be expressed as: "45×45/108×58/60"" which means the width is 60 inches.

(5) Gram weight - The gram weight of the fabric is generally the number of grams of fabric weight per square meter. The gram weight is an important technical indicator of knitted fabrics. Woolen woolen fabrics usually also use the gram weight as an important technical indicator. The weight of denim fabric is generally expressed in "ounces (OZ)", which is the number of ounces of fabric weight per square yard, such as 7 ounces, 12 ounces of denim, etc.

(6) Dyed weaving - also known as "dyed fabric first", refers to the process of dyeing yarn or filament first, and then using colored yarn to weave fabric. This kind of fabric is called "dyed fabric" and is produced Factories that produce yarn-dyed fabrics are generally called dyeing and weaving factories, such as denim and most shirt fabrics.

TAG:

Recommended

Good home textiles can also help with insomnia